Leistungen

Produktionsleitung

Alle Funktionen:

- Shopfloor Management

- Personal- und Ressourcenplanung

- Kennzahlen / Reporting

- Problemlösung

- Neuanläufe

Taskforce

In kritischen Situationen:

- Lieferbereitsschaft wieder herstellen

- Qualitätsprobleme beseitigen

- Kundenkommunikation

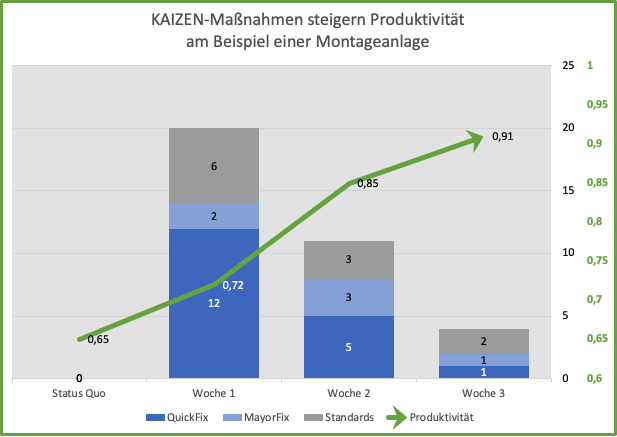

Steigerung der Produktivität

Gezielte Methoden:

- Waste-Walks und Housekeeping-Mentalität etablieren

- 5S und TPM in Kombination einführen

- Abläufe Standardisieren

- Training in Lean-Essentials

- Befähigung des Teams verbesseren und Motivation und Loyalität steigern